Join the construction of a wood pellet manufacturing plant in the Vosges!

The Damblain BioPellets project, developed by Jeferco in partnership with Thermofidev and Atlante Gestion, involves the construction of a wood pellet manufacturing plant located in France in the Vosges department (88). By valorizing waste from the wood industry (sawmills and forestry operators), this facility contributes to reducing dependence on fossil fuels and to the relocalization of French energy production.

With a production capacity of 120,000 tonnes per year of wood pellets for residential and industrial use, the Damblain BioPellets plant will allow households equipped with a pellet stove to avoid emitting 111,132 tonnes of CO₂ per year compared to gas heating.

*Heating value of wood pellets: 4.9 kWh/kg, carbon intensity of wood pellets: 0.0320 kg CO₂e/kWh, carbon intensity of gas heating: 0.221 kg CO₂e/kWh (Ademe)

Enerfip has already worked with the project leaders for a similar plant, Picardie Granulation, in mid-2023.

Plan 3D de représentation de l'usine Damblain BioPellets© Francky Parent - Architecte

The offer

The company Jeferco, a French company based in Lille, offers an investment opportunity in the financing of a wood pellet manufacturing plant named Damblain BioPellets located in Damblain in the Vosges (88) grouped within the company Jeferco Pellets Grand Est SAS.

OBJECTIVE

The crowdfunding campaign for this project aims to raise €1.8 million, with the possibility of increasing this to €2.4 million in the form of bridge debt.

USE OF FUNDS

The funds raised will be used to finance the studies of engineering firms, project management assistance, and the establishment of construction contracts with the aim of having all contracts in firm commitment for the financial closing scheduled for mid-2026.

SECURITY

Investors benefit from a first-rank pledge on the company holding the project to be financed.

REPAYMENT

The repayment of the bonds will take place through the obtaining of senior debt from conventional banking institutions.

More info about the sponsors in the project carrier tab

Specifications

Investment phases

- Investment open to everyone

End of project financing

The closing date for contributions may be extended at the request of the project owner.

The return on your investment will be calculated from the date the subscription certificates are generated, i.e. once all the funds have been received and the legal documentation has been signed by the project owner.

Resources

Simulator

Investment simulation

Damblain BioPellet - Obligation 8%/year over 1.5 year

Simulation - Rate : 8% / year on 1.5 ans

Initial investment:

€1,000

Repayments and interest:

€1,120

In 2 transfers

| Date | Interest* | Capital | Amount |

| 03/10/2026 | €80 | €0 | €80 |

| 03/04/2027 | €40 | €1,000 | €1,040 |

| Total | €120 | €1,000 | €1,120 |

*Gross interest before tax, including all fees (view taxation) The result presented is not a forecast of the future performance of your investments. It is only intended to illustrate the mechanics of your investment over the investment period. The evolution of the value of your investment may vary from what is shown, either increasing or decreasing. | |||

The project

Wood Pellet Manufacturing Plant in Damblain

The Damblain BioPellets project is a ready-to-build wood pellet manufacturing plant that will be located in the commune of Damblain in the department of Vosges (88). The plant is scheduled to be operational by September 2028.

Located on the site of a former NATO base, owned by the General Council of Vosges and the Department, the future plant has obtained environmental authorization and building permits for its realization.

The Enerfip financing will enable the completion of the final studies and the establishment of the last contracts in view of a senior financial closing by mid-2026.

The future pellet production plant will have a production capacity of 120,000 tonnes per year. Although the average pellet consumption depends on several factors (size of the residence, insulation, weather, thermal comfort required), the annual consumption of a household is estimated at 1.5 tonnes. This production tool will therefore have the capacity to meet the needs of approximately 80,000 households equipped with a pellet stove.

Wood Pellets

Pellets, also known as wood pellets, are small cylinders of wood (ranging in length from 10 to 30 mm, with a diameter of 9 mm), made from the compaction of wood by-products. They are manufactured from natural waste (from sawmills and/or forestry operators), which is refined, dried, and then assembled under high pressure. Thus, no tree is specifically felled for their manufacture.

1. An Economical Heating Solution

source: Propellet

Despite an energy price crisis in 2022 (which has since returned to normal), heating with wood pellets is significantly cheaper compared to electricity, propane gas, heating oil, or natural gas.

2. An Ecological Heating Solution

Unlike fossil fuels such as gas or oil, which take millions of years to replenish their stock, the wood resource regenerates quickly, which does not significantly increase the concentration of CO2 in the atmosphere over the resource’s regeneration period. The carbon footprint is low, meaning the amount of carbon dioxide emitted during combustion is practically the same as when a growing tree absorbs this amount of carbon dioxide. Consequently, carbon dioxide emissions are reduced by more than 90% compared to heating oil. Additionally, the production of wood pellets is based on waste from forestry activities and related industries.

3. A Local Heating Solution

Evolution of wood pellet production and consumption in France

source: Propellet

French consumption of pellets exceeds production. Therefore, there is an interest in creating production facilities in the country to strengthen France’s energy independence. Wood pellets manufactured in France are subject to strict quality standards, ensuring a high-performance and reliable product. By purchasing locally, you benefit from complete traceability, ensuring that the pellets come from sustainable and responsible sources. Certifications such as DINplus or ENplus attest to this quality.

Additionally, the procurement strategy for this project involves sourcing raw materials within a 150 km radius of the manufacturing plant. Several letters of intent have been received from suppliers of forestry waste and sawmills as part of the supply for this plant.

4. A Simple Heating Solution

Technological advancements over the past few decades have made pellet stoves reliable and efficient, requiring only a steady supply of quality pellets and basic regular maintenance. The autonomy of stoves can reach up to 3 days, and that of boilers up to 1 year. For pellet stoves, the bags of pellets weigh between 10 kg and 15 kg. They are easily storable in a garage, protected from humidity, and avoiding direct contact with the ground. For a pellet boiler, the minimum space required for storage is approximately 1 m3. There are turnkey solutions such as textile silos that can be positioned up to 20 meters from the boiler.

Many industries are also converting their gas, oil, or coal boilers to pellet boilers to meet decarbonization and carbon quota objectives, thus multiplying the commercial outlets for the project.

To learn more about wood pellets: Propellet (National Association of Wood Pellet Heating Professionals)

Wood Pellet Manufacturing Process

Wood pellets are made from by-products of sawmills, such as wood cuts, sawdust, or wood chips, as well as forestry operation waste such as tree tops, small branch residues, and low-diameter thinning wood. The pellet manufacturing process involves compacting sawdust and chips to make them usable for pellet boilers and stoves. This process consists of several steps to produce high-quality, high-performance pellets that meet standards.

1. Bark Removal

First, the various cutting waste is separated from its bark.

2. Crushing

All inputs are crushed to obtain fine sawdust.

3. Drying

The obtained sawdust is dried using a biomass boiler (also fueled by wood waste) to control the moisture content, which must be less than 10%.

4. Dry Crushing

A second crushing step is performed with the dry sawdust.

5. Compaction

The sawdust is then compacted by a special press to form the pellets. This high pressure allows the cohesion of the pellet without any binder or additive.

6. Cooling

The pellets are cooled (the action of the press heats them) and sifted to remove all dust.

7. Storage

8. Packaging

The pellets are packaged in bags or in bulk for specific use.

Project owners

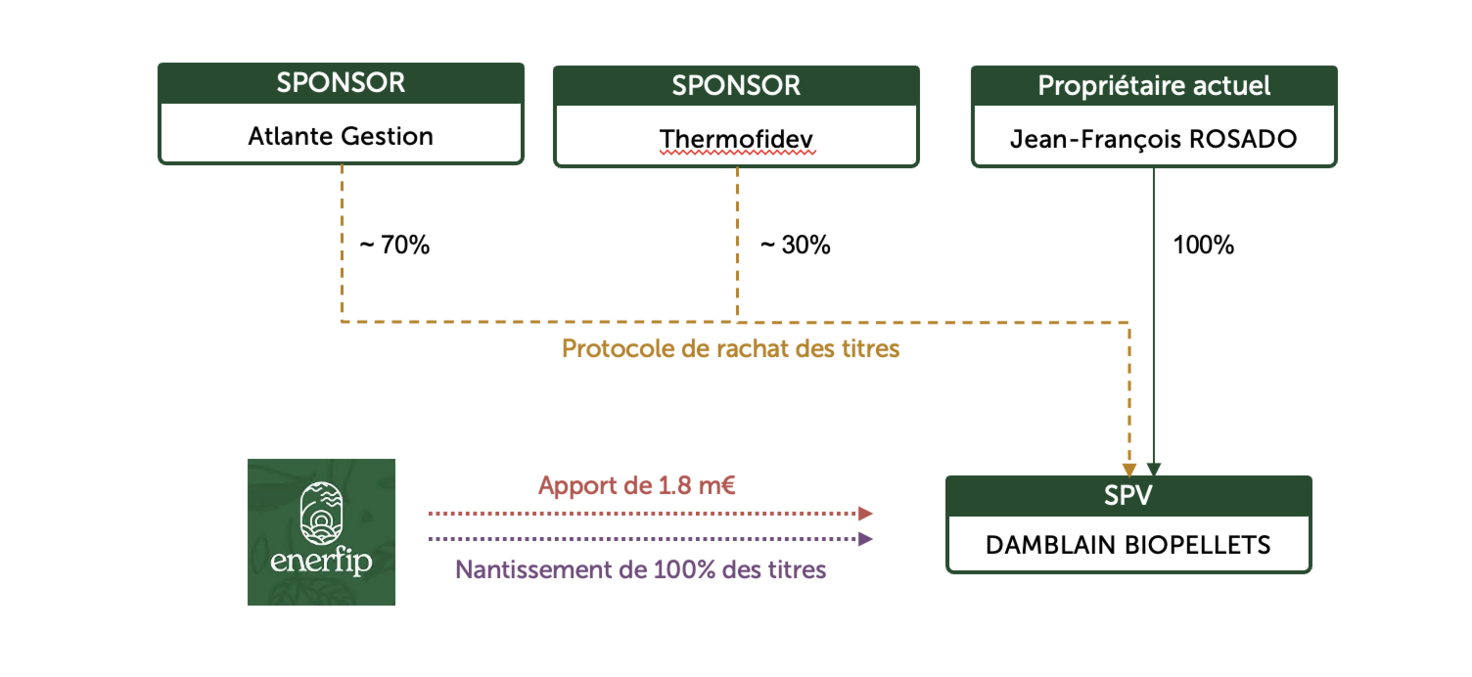

🤝 Agreement with Atlante Gestion and Thermofidev

The company Jeferco, developer of the project and holder of the authorizations, signed in May 2024 a memorandum of understanding with Atlante Gestion and Thermofidev to set up a partnership in which these two players:

-

take charge of the construction and operation of the plant

-

define the terms of taking over the entire project capital at the time of project financing.

Atlante Gestion and Thermofidev would acquire the entire project at 70% and 30% respectively.

👨💼 Atlante Gestion: Independent Portfolio Management Company

Atlante Gestion is a portfolio management company (approved by the Financial Markets Authority) that collects funds from institutional investors, pension funds, insurances, and private investors, and invests them in real assets in the sectors of:

- energy transition (notably solar, biogas, biomass, granulation)

- infrastructures

- decarbonization of maritime transport.

Atlante Gestion currently manages nearly 1 billion € in assets in the sectors of infrastructures (Atlante Infrastructures 1 Fund) and energy transition.

👷 Thermofidev: Biomasse Specialized Project Management Assistance

Thermofidev is a Project Management Assistance company founded by Jean-François Saujet and Simon Linéatte with 55 years of combined experience.

The teams of Atlante Gestion & Thermofidev have already completed a wood pellet production project: Picardie Granulation, located in Chaulnes in the Somme, with a capacity of 100,000 tons per year. This project was the subject of a successful collection at Enerfip in mid-2023.

This project, currently in the reception phase, Thermofidev is developing the Damblain BioPellets project alongside Atlante Gestion, to leverage their experience.

Our analysis

Risk overview

Construction risks

Risk of construction delays or failure to complete the work

Mitigation methods

Atlante et Thermofidev ont œuvré à la correcte construction du projet Picardie Granulation depuis 2023. Malgré quelques aléas survervnus sur le chantier, l’usine a été livrée en mars 2025, et devrait débuter ses essais de granuelr dès début mai 2025. Au travers de ce chantier les deux entreprises ont démontré leur capacité à mener à bien la structuration juridique et financière, le développement, et la maîtrise d’œuvre d’une usine de fabrication de granulés de ce type et cette taille. Une réserve de contingence a été mise en place afin de faire face à d’éventuels surcoûts de construction.

Development risk

Risk relating to authorizations issued to the company and land, and third-party appeals against authorizations issued.

Mitigation methods

Le projet Damblain Granulation arrive à la fin de son développement. Les dernières étapes concerneront la négociation des contrats O&M et d’EPC, la transormation des LOI d’achat en contrat mais aussi le paiement du raccordement et frais de dossiers liées aux demandes de subventions. La vente du foncier a été sécurisée. Le projet détient un Permis de Construire, une Autorisation Environnementale et une Autorisation d’Exploiter, transférés sous la société de projet et purgés de tout recours.

Refinancing risk

Credit risk related to the company's ability to refinance and meet its debt obligations.

Mitigation methods

Le projet Damblain Granulation est un projet d’infrastructure impliquant près de 67 millions d’euros de CAPEX. À ce jour, grâce au support d’ADENFI, société de conseil financier mandaté par Jeferco Pellets (société porteuse de projet), le projet a obtenu plusieurs LOI pour la dette Senior. D’autres LOI concernant la dette junior, nécessaire au déblocage de la dette senior, sont également en cours d’obtention par la société de projet. Le business plan prend des hypothèses conservatrices et s’appuie un plan de service de la dette avantageux qui devrait faciliter la sécurisation de lignes obligataires senior et junior et permettre le closing financier du projet durant le 1er semestre de 2026.

Investing in this participatory financing project involves risks, including the risk of total or partial loss of the capital invested. Your investment is not covered by the deposit guarantee schemes established in accordance with directive 2014/49/EU of the European Parliament and of the Council. Your investment is also not covered by the investor compensation schemes established in accordance with Directive 97/9/EC of the European Parliament and of the Council. Return on investment is not guaranteed. This is not a savings product, and we recommend that you not to invest more than 10% of your net assets in participatory finance projects. You may not be able to sell the investment instruments when you wish. If you are able to sell them, however, you may incur losses.